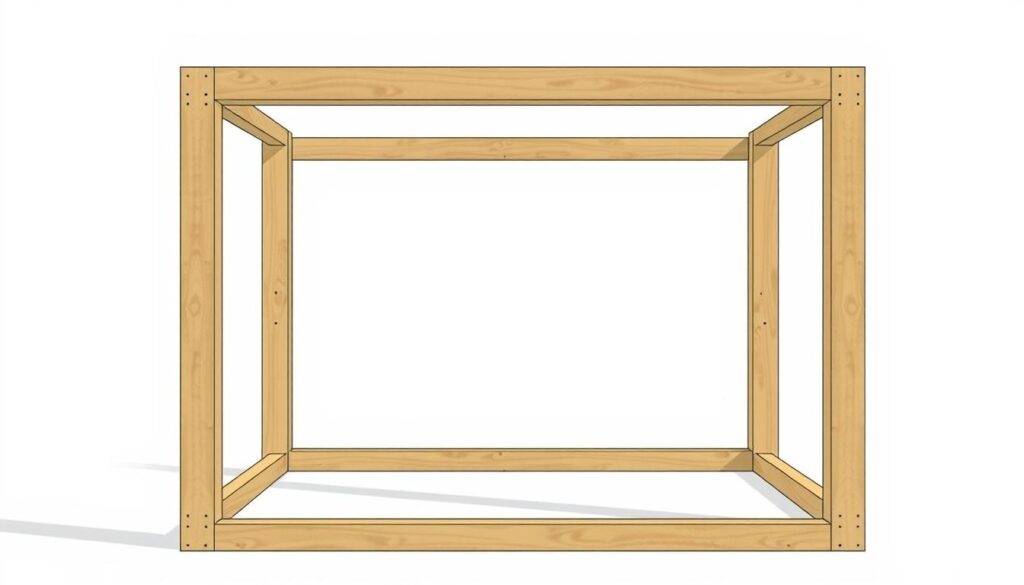

Build confidence from day one. A truly sturdy 100 gallon aquarium stand is a platform that holds thousands of pounds with quiet certainty. It should look like furniture, protect your fish, and last for years.

Know what to expect up front. By the end of this guide you’ll not only think strong enough, you’ll know the checks to confirm strength, how to place supports, and how to brace against sideways forces.

Decide early if you will build or buy. Measure the footprint to match your long tank decided plan, and pick materials made for long life rather than quick fixes.

Craftsmanship matters. Precise cuts, square assemblies, and steady fastener patterns turn a shaky project into a rock-solid base you might say could park something heavy on.

Sketch your plan, list the parts, and note the tests you wanted make sure before driving the first screw. This intro sets the goal: a furniture-grade front with full access and proven strength.

Key Takeaways

- Understand how to confirm a design is strong enough before building.

- Map the stand footprint to your long tank decided layout.

- Choose durable materials over short-term convenience.

- Use precise cuts and consistent fasteners for lasting stability.

- Document plans and checks before starting construction.

Why a well-built 100 gallon aquarium stand matters today

A reliable frame removes worry and keeps your system safe through daily use. A fully equipped 100-gallon setup can weigh well over 1,000 pounds. The base must confidently stand up to that load without creeping or transmitting vibrations.

Safety, stability, and peace of mind for your aquatic community

The real hold weight problem isn’t only vertical collapse. Subtle racking and lateral shift wear joints over time. A sliding sideways load can loosen fasteners and misalign the tank slowly.

Good framing stops tiny movements. Robust bracing reduces micro-motion that stresses silicone seams and equipment. That protection preserves fish, corals, and your investment.

- Redundancy: Plan enough prevent rotation so one loose member won’t let the cabinet deform.

- Longevity: Strong frames resist seasonal wood movement and reduce delayed hold weight problem months later.

- Home safety: Level, stable supports lower tipping risk and protect floors, pets, and children.

Understanding how your frame counters torsion and problem lateral movement guides every build choice that follows. Build to move on only in life, not your tank.

Sizing and load basics for a 100 gallon aquarium stand

Know the full-system mass before you place a single brace. Add water (8.34 lb/gal), glass or acrylic, substrate, rock, sumps, and equipment. Then apply a 15–25% safety factor so the design is not marginal.

Force follows the rim. The heaviest loads drop near the perimeter where glass meets the frame. Plan continuous support top bottom along the footprint so that load travels straight into legs and the floor.

On the short side long axis, spans flex more across the long dimension. Add internal supports under the long side to keep the top dead flat and reduce visible deflection.

- Corner care: Treat each corner short side and long side as a bearing location that must transfer vertical force with minimal bend.

- Compression lines: Visualize corner corner short and long edges as columns; center braces must land beneath load paths, not under unsupported glass.

- Stress risers: Cutouts near january showing corners weaken edge continuity—reinforce these zones.

Also check the back side top rail: it ties the frame to resist racking. Avoid oversized spans between verticals on the long side by selecting thicker members or adding posts to keep deflection below visible thresholds.

Framing fundamentals: 2×4 strategy and vertical support layout

A precise top-and-bottom perimeter is the foundation; build it first and everything else lines up cleanly.

Perimeter frame top and bottom along the tank footprint. Start with straight, dry 2x4s laid as matching top and bottom rails. Keep crowns oriented the same way so bearing surfaces stay flat. This rectangle sets the load path into the legs.

Placing vertical members at corners and intervals to prevent rotation

Place perimeter vertical members at all four corners first. Then add posts along long runs so spans remain short. When vertical members prevents rotation, the top and bottom act as tied columns and resist torsion.

When to add 2×4 sides every corner and along the long side

Reinforce high-load zones by adding 2×4 sides every corner on both long faces. If in doubt, add 2×4 sides in mid-span to cut bounce. If your plan called for it, stated add 2×4 beneath mid-span rails to stop visible deflection.

Level, square, and fastener patterns that keep the stand strong enough

Lock 2×4 corner corner joints with full contact, screws, and gussets. Use a regular fastener pattern and adhesive at key seams so the frame acts as one unit. Verify enough 2×4’s hold the load by aligning legs under rim rails and checking level and square as you go.

- Start with a true rectangle.

- Place perimeter vertical members under rim-supporting rails.

- Add 2×4 sides every long panel when spans grow.

Sheathing and bracing: plywood back side, fence boards vertically, and stopping lateral movement

A stout shear panel can turn a wobbly cabinet into a resolute frame that resists sideways force. A well-fastened 3/8″ ply back side acts as the main shear element. Attach the piece ply back with screws on a tight grid — about 6–8 inches on edges and 8–12 inches across the field — and use construction adhesive to keep it glued to the rails.

Fence boards vertically on the front and sides look great but add little shear. If you plan adding plywood only at the back, add corner blocking, interior horizontal cleats at the upper third, or diagonals to prevent torsion.

When a full skin ply totally isn’t practical, sheathing could panels be staggered with blocked seams so the load transfers across joints. Holes sheathing acceptable for plumbing as long as you frame the openings and keep fasteners nearby to preserve the shear path.

- Middle ground: piece ply back + 6–12″ side shear strips mimics a wrap plywood like feel without full enclosure.

- Fastener technique: pre-drill near edges, glue panels, and add extra screws where panels meet rails — cope413 stated this in many build threads.

- Final tip: combine a robust ply back side, corner blocking, and one extra shear element for a cabinet that stays rock-solid under load.

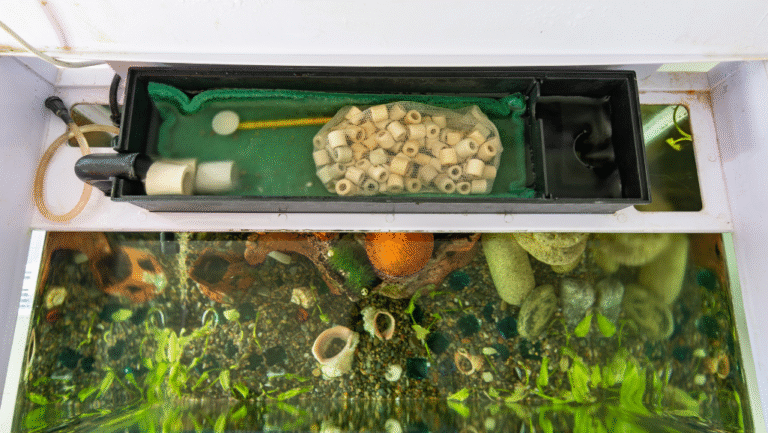

Finish, function, and final checks before filling

The final phase blends style and safety. Choose front facings that hide hardware but never cut into load-bearing members. If you put wood slats or shaker doors, fasten them to a face frame or cleats so the core framing remains untouched.

Do a dry run in the room. Place the completed cabinet in its final spot and check for rocking. Shim where needed so the unit sits flat before any water arrives.

Inspection checklist: square, wobble-free, ready for water

- Measure diagonals to confirm it is square.

- Re-check fasteners and tightness around any back january showing cutouts.

- Verify the top is level both front-to-back and left-to-right; use a foam or neoprene pad only after framing flatness is assured.

- Stress test with distributed weight to listen for creaks and ensure the build feels totally adequateclick expand in confidence.

- Confirm doors and access panels clear sump plumbing and that ventilation will control humidity.

Finish interiors with sealed edges and oil-based primer or marine varnish in splash zones. Many builders who stands since long borrow tricks from a stand catchemall posted thread and then adapt them.

Keep a short build log of materials and choices for sharing with polcommunity memberview badgesjoinedapr peers or referencing later—names like kateateractive memberview badgesjoinedoct, 2016messages28reaction score9 rating, and 2014messages442reaction score88locationorange county show how community records add value.

Conclusion

A well-built base ties together smart load paths, tight framing, and purposeful sheathing into lasting stability. Focus first on a flat, level top and keep spans short so the load moves cleanly into the legs. Add a locked back shear panel and use clean, secure fasteners to stop racking.

Keep aesthetics practical. Choose front finishes that look refined but never cut into load-bearing members. Preserve access for plumbing and maintenance so form follows function.

Trust your checks: level, square, and stress-test before any water arrives. Build with confidence, and every maintenance task and aquascape change becomes easier. A solid 100 gallon aquarium stand makes your aquatic world safer and more enjoyable.